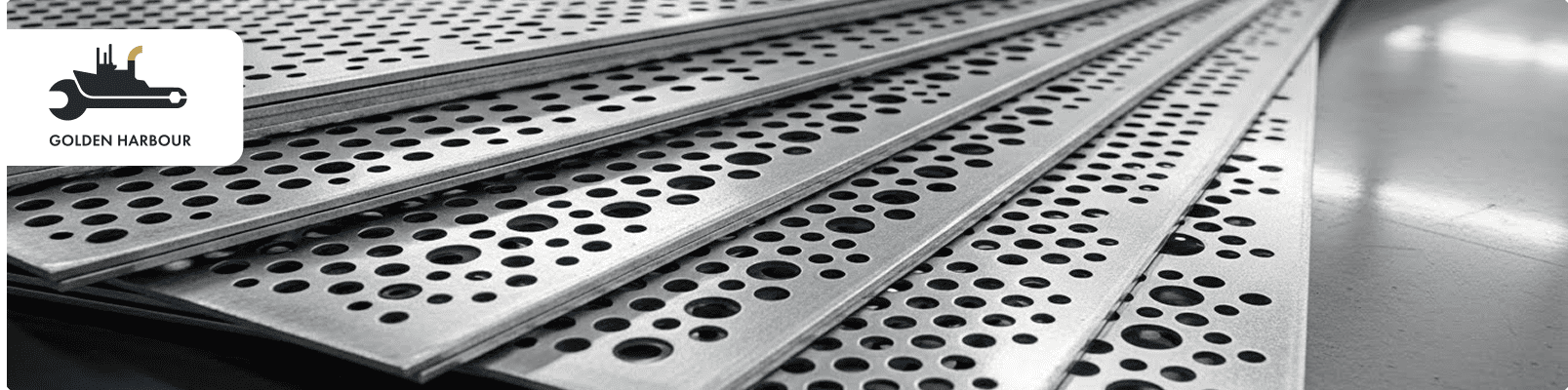

Perforated sheets, a type of flat sheet metal that has been punched out with holes in a regular pattern, have an outstanding combination of industrial efficiency, safety, and design flexibility in many different applications. Perforated metals, or "hole-punched" sheets, are used throughout the manufacturing industry for a variety of purposes. Examples include: sound control, airflow, protection, filtration, and even for aesthetic purposes.

At the heart of the perforated sheet, metal is simply a flat piece of metal, which has been mechanically punched out using a hole-punching operation, which produces holes in a regular pattern. Perforated sheets can have various hole shapes, sizes, and spacing, depending on the specific use or application of the sheet. Common examples include the use of perforated sheets for industrial machines and for some architectural applications on facades to create a visually appealing surface.

A variety of materials, including aluminium, brass, mild steel, carbon steel and stainless steel may be used to create perforated sheets; however, the perforation patterns can also be tailored to suit individual users' needs. This guide details how perforated sheets are produced, the elements of perforated sheet design and the typical applications of perforated sheets.

Manufactured using the punch/stamping method, perforated metal sheets are created by using a series of uniform throughout the board and/or as an assembly of non-linear shapes dimpled puncture holes; therefore they provide structural stability while reducing weight and allowing free passage of air/liquid.

When designing your perforated metal sheet you can choose to create a lightweight product that resists rust, or a decorative piece based on the type of material you choose. The diverse array of products created using these materials has contributed to their widespread use throughout the manufacturing, industrial, engineering and manufacturing fields.

Controlled airflow, separation, screening or protection are some of the uses for perforated sheets; their uses include:

By combining both function and durability, perforated sheets provide engineers and designers increased flexibility.

See also: Understanding the Benefits and Applications of Stainless Steel Round Bar

Applications vary, so the types of materials that can be used will also be different; therefore, there are many additional types of perforated sheets, and these include:

In this regard, a stainless steel perforated sheet is one of the best options to choose from for any type of application where corrosion Resistance, Hygiene and durability is a requirement.

The carbon steel perforated sheets are used in many heavy duty industrial applications because they are affordable and strong. A carbon steel perforated sheet manufacturer that you can trust will produce products with a high value for load-bearing and structural benefit.

A mild steel perforated sheet is typically used for applications requiring High Strength at a low cost/as compared against using Alloy Steel, however mild steel has advantages for fabricating products easily (e.g., machinery guards/enclosures).

A Perforated Brass Sheet may be used for Decorative,, Architectural or Corrosion Resistant applications due to their Decorative qualities, thus making them suitable for use in Interior Panels & Architectural Design applications.

Choosing a suitable perforated sheet is based on several important considerations.

They include:

When you work with an established perforated sheet supplier, you will have the experience and expertise to obtain the right balance of performance and cost.

See also: Exploring Aluminium Bars: Their Types, Characteristics, and Applications

The shape of holes can have an impact on both their properties and performance. Hole shapes can vary greatly in design; the main ones include round, square, slotted and decorative. Round hole perforated carbon sheets are a very common choice since they provide the most consistent strength throughout the sheet.

The dimensions of a filter's holes, how far apart the holes are located, and how many holes a filter has all impact how much air can flow through the filter, how well the filter performs and the strength of the filter. Therefore, when you are designing your filters it is important to maximize how small of a material you can make for your filter.

Filter sheet thickness determines filter design strength and flexibility as well as its weight. A thicker sheet will provide greater strength than a thinner sheet; however, because they use less filtered surface area than thicker sheets, they also possess less flexibility and thus require less room in an aircraft due to their lower density (the amount of air that passes through per square inch of a hole).

Appropriate thickness selection will provide the optimum combination of strength versus weight.

Typically, the manufacturing of perforated sheets requires the following:

A reputable perforated sheet supplier should provide a consistent level of quality and accuracy and meet the manufacturer's specifications and standards for the appearance of the final product.

See also: Brass Bars in Marine Engineering: Why They Are the Trusted Choice!!

The capabilities of perforated sheets vary widely. The applications commonly include the following industries:

Machines and Manufacturing Provide Perforated sheets (Filters and Sieves), Machine Guards and Safety Equipment, Acoustic Panels for Noise Reduction, Ventilation Systems and Airflow Equipment, Architectural Façade Ceilings.

Oil and Gas Mini & Separation Systems, Agricultural Processing. Golden Harbour has regularly provided Perforated Sheets made from a range of metals to these industries since it started operations. The perforation of the Perforated Sheets produced by Golden Harbour meets the necessary specifications of each Industry, with the assumption that the materials used are from approved suppliers and that they can be customised to fit individual Industry requirements.

While perforated sheet metal may appear to be nothing more than a flat, hole-punched, piece of steel, it has been carefully engineered to enhance its performance, safety, and efficiency in many different industries. Choosing the appropriate combination of materials, design elements, and production techniques will provide the end-user with a superior performing product in both industrial and/or architectural settings.

Golden Harbour has an extensive history in working closely with our customers to provide reliable solutions to meet their specific design and functional requirements by drawing on the large quantities of perforated sheet metal that we have in stock. Golden Harbour has a wealth of experience, as well as a wide variety of types of perforated metal products, to collaborate with both its Customers and the suppliers it represents to provide assistance in evaluating and determining the most suitable products for each Customer's distinct perforated metal requirements, including matching the performance of each Customer's unique specifications and functional needs.